- Home

- Products

- Water Based Epoxy Material and Coating

- Epoxy Flooring Coating

- Epoxy Flooring Coating, HCT-2766

Epoxy Flooring Coating, HCT-2766

Product Types

A component:HCT-2766A

B component:HCT-2766B

PRODUCT DESCRIPTION:

The product is 2 component system waterbase epoxy flooring paint, which is suitable for cement(-sand) mortar floor.

Typical Applications

Cement floors, walls and machinery in areas such as:

Underground parking lot

Factories, warehouses and hangars

Hospital, shopping centers, schools and laboratories

Food and beverage industry

Chemical industry

Retaining walls

Seamless flooring

Waterproofing concrete slabs before floor overlay

Product Characteristics

Excellent abrasion resistance property

Great adhesive force

Good impact resistance and high hardness

High fullness and decorative performance

Waterbase and pro-environmental product, which is a good choice for traditional solventbase series product

| Color | all kinds of color |

| Volume Solid Content | 45 ± 1% Operation Ratio: A : B=4 : 1 |

| Surface Drying Time | ≤ 4 hours (25 ℃ , relative humidity ≤ 85%) |

| Recoat Interval | ≥ 8 hours (25 ℃ , relative humidity ≤ 85%) |

| The Thickness of the Drying Film | 50 um (flatting surface, once) |

Theoretic Coating Rate

About 7-8 m²/kg (once, flatting surface, actual coat rate will be changed according to different items like coat way, operate tools and the smooth property of the coated surface.)

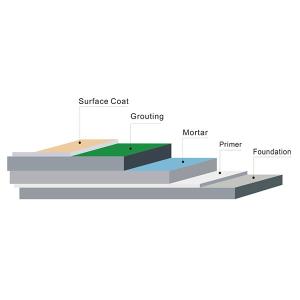

Match System

Waterbase Epoxy Flooring Primer (once): (HCT2788A : HCT2788B= 4 :1 Weight ratio)

Waterbase Epoxy Tie coat (once or twice): (HCT2777A : HCT2777B= 4 :1 Weight ratio)

Waterbase Epoxy Top Finish (twice): (HCT2766A : HCT2766B= 4 :1 Weight ratio)

Application Data

Construction ways: Roller coat, Brush coat, Spray coat

Construction tools: 1. Rollers 2. Hairbrush 3.Airbrush

Dilution methods: Clear pure water (0-5%)

Tools washing way: Use clear water to wash immediately after construction

Foundation Treatment

The foundation surface (flooring surface) should be sanded evenly and got rid of powder dust, rust, oil stain and other impurity materials for 4 weeks protective cement or cement mortar flooring. If crackness or damage are appeared on the surface, it should be recoated using the same materials as previous base materials, the protective period should be over 1 week after repair.

Guidence

Foundation treatment

Coat HCT2788 epoxy primer once

Coat the tie coat HCT2777 as per your practical requirement

Coat HCT2766 Epoxy top finish once or twice

Package

A component: 20kg plastic drum

B component: 5kg plastic drum

Should be stored under dry, shadow and cool place and the expiry date is 12 months under the normal temperature (20℃/68℉)

Attention

The rollers, brushes and other tools should be soaked into the water for about 5 minutes before constuction

A and B components should be mixed correctly and stired evenly before construction.

The dilution proportioning should be chosen according to the construction temperature.

Humidity and the appropriate viscosity should be made as per the requirements.

The mixture should be stired evenly and waited for a while, it should be used after 15 minutes

A component belongs to waterbase coatings which should not be polluted by organic solvents,

B component should not be diluted by water

The coatings which has been mixed should be used in 4 hours, unfinished coat can’t be poured back into the previous package, it should be stoped using if appears thickened

The coatings should not be over-diluted no matter spary coat or roller coat in order to protect propertys of the film

Pay attention to the labor protection during the construction

Safety

Keep the circulation of air during construction

Use protective masks, gloves and other protective tools to prevent skin or eyes from being contaminated and nose being absorped over amount of coating frog

Use lots of water to wash eyes if contaminated and ask doctors for help

Cover the tops of the products during the construction rest

Keep the products away from the children

Tianyi Chemical Engineering Material Co., Ltd.

Tel.: +86-757-29322906

Fax: +86-757-22900652