- Home

- Products

- Water Based Epoxy Material and Coating

- Epoxy Flooring Coating

- Epoxy Flooring Coating, HCT-2777

Epoxy Flooring Coating, HCT-2777

Product Types

A component: HCT-2777A

B component: HCT-2777B

PRODUCT DESCRIPTION:

As the two-component flooring tie coat in the water-base epoxy flooring series, apply between the primer and surface coating, it can promote the loading capacity and serving life of the coating systems.

Typical Applications

Cement floors, walls and machinery in areas such as:

Underground parking lot

Factories, warehouses and hangars

Hospital, shopping centres, schools and laboratories

Food and beverage industry

Chemical industry

Retaining walls

Seamless flooring

Product Characteristics

Good attachment in the paint film

High hardness

Anti shock resistance

Promote the coating system loading capacity and application life time of the coating system.

Waterbase product, safe and environmental, it is an ideal product and can instead of the traditional product.

| Color | Grayish yellow or customers' require |

| Volume Solid Content | 41.3±1% ( A : B=4 : 1 weight ratio) |

| Surface Drying Time | ≤ 4 hours (25 ℃ , relative humidity ≤ 85%) |

| Recoat Interval | ≥ 24 hours (25 ℃ , relative humidity ≤ 85%) |

| The Thickness of the Drying Film | 300-800 um (flatting surface, once) |

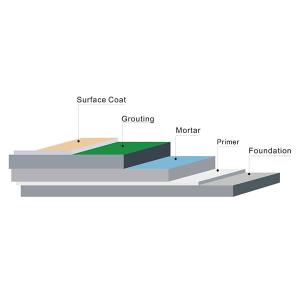

Match System

Waterbase Epoxy Flooring Primer (once): (HCT-2788A : HCT-2788B=4 :1 Weight ratio)

Waterbase Epoxy Tie coat (once or twice): (HCT-2777A : HCT-2777B=4 :1 Weight ratio)

Waterbase Epoxy Top Finish (twice): (HCT-2766A : HCT-2766B=4 :1 Weight ratio)

Application Data

Construction ways: Knife coat

Paint mixing ratio (weight ratio): A : B=4 : 1

Tools washing way: Using clear water to wash immediately after construction

Construction conditions: The temperature of flooring should not be below 8℃ during the construction, moisture content ≤10%, air humidity≤85%

Theoretic Coating Rate:

As epoxy thick mortar layer:

A: B: 80 mesh quartz sand = 4:1:3 (weight ratio),

mortar layer of dry film thickness per mm needs A component 0.46kg , about coating rate is 3m²/kg (after mixing all the components)

As a piece of the thin epoxy mortar layer:

A: B: 100 mesh quartz powder = 4:1:3 (weight ratio),

The thickness of dry film per mm of a mortar layer needs A component 0.56kg, coat rate of about 3m²/kg (after mixing all the components)

Foundation Treatment

New cement mortar flooring should be maintained over 5 weeks in winter, 4 weeks in summer

Remove loose material and other contaminants on the ground, using epoxy mortar to repair the ground which should be maintained over 3 days in winter, 2 days in summer

Attention

Mix the component A and component B exactly according to the proportion, and stri completely, and then place it for 20 minutes. If not strict to matching, it will cause bad on the coating film even have the quality problem

This is the water-base coating, it needs to invoid the organic solvent pollution

It needs necessary labor protection job during operation

Package/Storage

A component: 20kg iron drum

B component: 5kg plastic drum

Stored in a cool, dry and ventilated place, The shelf life in normal temperature could reach 12 months (20℃/68℉)

Safety

Keep air circulation during construction

Use protective masks, gloves and other protective tools to prevent skin or eyes from being contaminated and nose being absorped over amount of coating frog

Using lots of water to wash eyes if contaminated and ask doctors for help

Cover the tops of the products during the construction rest

Keep the products away from the children

Tianyi Chemical Engineering Material Co., Ltd.

Tel.: +86-757-29322906

Fax: +86-757-22900652